The Role of Three-Roll Idlers in Enhancing Equipment Longevity

25/05/08 14:00

The Role of Three-Roll Idlers in Enhancing Equipment Longevity

Table of Contents

1. Introduction to Three-Roll Idlers

2. Understanding Equipment Longevity

3. How Three-Roll Idlers Work

3.1 Mechanism of Action

3.2 Types of Three-Roll Idlers

4. Benefits of Using Three-Roll Idlers

4.1 Enhanced Load Distribution

4.2 Reduced Wear and Tear

4.3 Improved Material Flow

5. Maintenance Best Practices for Three-Roll Idlers

5.1 Regular Inspections

5.2 Cleaning and Lubrication

6. Common Issues with Idlers and Solutions

6.1 Misalignment Problems

6.2 Bearing Failures

7. Case Studies: Success Stories with Three-Roll Idlers

8. Conclusion

9. FAQs

1. Introduction to Three-Roll Idlers

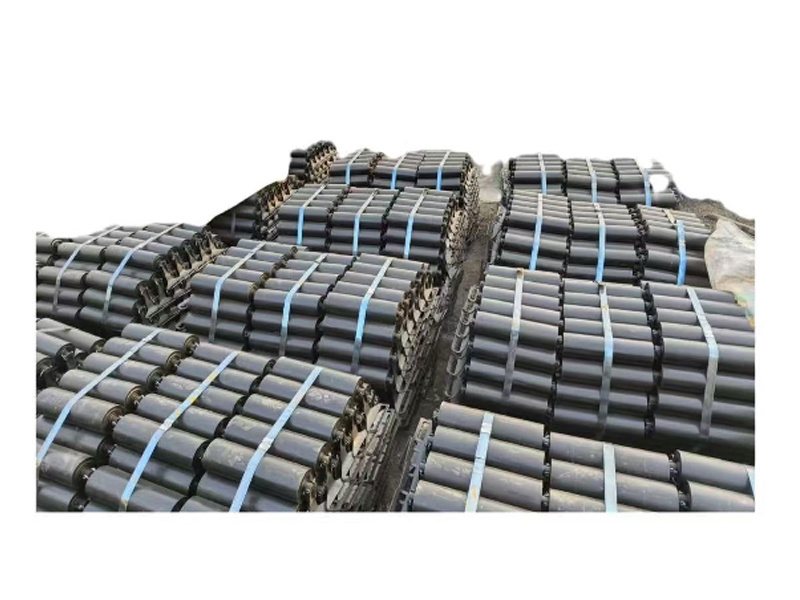

Three-roll idlers are essential components in various material handling systems, primarily within the manufacturing and mining industries. They play a crucial role in supporting conveyor belts, facilitating the efficient movement of materials over extended distances. By understanding how three-roll idlers function, we can appreciate their significance in prolonging equipment life and enhancing operational efficiency.

2. Understanding Equipment Longevity

Equipment longevity refers to the lifespan of machinery and its components, essentially measuring how long they can operate effectively before requiring replacement or extensive repairs. Factors affecting equipment longevity include wear and tear from usage, environmental conditions, and the quality of maintenance practices. By using three-roll idlers, businesses can significantly improve the durability of their equipment, ensuring smoother operations and reduced downtime.

3. How Three-Roll Idlers Work

3.1 Mechanism of Action

Three-roll idlers consist of three cylindrical rolls arranged in a triangular formation. This configuration allows for the even distribution of the load across the conveyor system. The idlers support the weight of the conveyor belt and the materials it carries, minimizing friction and wear on both the belt and the underlying structure.

3.2 Types of Three-Roll Idlers

There are various types of three-roll idlers, including:

- **Crowned Idlers:** Designed to keep the belt centered, crowned idlers facilitate smoother material flow and minimize edge wear.

- **Flat Idlers:** These offer straightforward support for the belt, but may lead to increased wear if not properly aligned.

- **Adjustable Idlers:** These can be modified to accommodate different load types and conditions, providing flexibility in operations.

Understanding these types allows businesses to select the most suitable idler for their specific needs.

4. Benefits of Using Three-Roll Idlers

4.1 Enhanced Load Distribution

One of the primary benefits of three-roll idlers is their ability to distribute loads evenly. This balanced approach minimizes stress on individual components, thereby reducing the risk of failure and extending the overall life of the equipment.

4.2 Reduced Wear and Tear

By decreasing friction between the conveyor belt and the idlers, three-roll idlers significantly reduce wear and tear on both the belt and the machinery. This translates to lower maintenance costs and fewer replacement parts over time.

4.3 Improved Material Flow

The triangular arrangement of three-roll idlers promotes a smoother and more efficient flow of materials. This increased efficiency not only enhances productivity but also reduces the likelihood of blockages and associated downtime.

5. Maintenance Best Practices for Three-Roll Idlers

5.1 Regular Inspections

To ensure the longevity of three-roll idlers, regular inspections are crucial. Technicians should check for signs of wear, misalignment, and other potential issues that could hinder performance.

5.2 Cleaning and Lubrication

Keeping idlers clean and adequately lubricated is essential for optimal performance. Dirt and debris can increase friction and wear, while proper lubrication minimizes wear on bearings and other moving parts.

6. Common Issues with Idlers and Solutions

6.1 Misalignment Problems

Misalignment can lead to premature wear and inefficiencies. Regular alignment checks and adjustments can help mitigate this issue, ensuring that the idlers function as intended.

6.2 Bearing Failures

Bearings are critical components of three-roll idlers. Regular lubrication and inspection can prevent bearing failures, which can cause significant downtime and costly repairs.

7. Case Studies: Success Stories with Three-Roll Idlers

Several industries have witnessed notable improvements in equipment longevity by implementing three-roll idlers. For instance, a mining company reported a 30% reduction in conveyor belt wear after switching to three-roll idlers, demonstrating the effectiveness of this technology in enhancing equipment performance.

8. Conclusion

Three-roll idlers play a pivotal role in enhancing equipment longevity, offering benefits such as improved load distribution, reduced wear and tear, and efficient material flow. By understanding their function and implementing best maintenance practices, businesses can optimize their operations and reduce costs. Investing in high-quality three-roll idlers is a strategic choice for any industry reliant on material handling systems.

9. FAQs

1. What are three-roll idlers used for?

Three-roll idlers are primarily used in conveyor systems to support and stabilize the conveyor belt, ensuring efficient material handling.

2. How can I tell if my three-roll idlers need maintenance?

Signs that idlers may require maintenance include unusual noises, visible wear, misalignment, or fluctuating performance.

3. What benefits do three-roll idlers offer over traditional idlers?

Three-roll idlers provide better load distribution, reduced friction, and improved material flow, all of which contribute to increased equipment longevity.

4. Can three-roll idlers be used in all types of conveyor systems?

While three-roll idlers are versatile, their suitability depends on the specific application and material being transported. It's essential to evaluate the operational conditions before implementation.

5. How often should three-roll idlers be inspected?

Regular inspections are recommended at least monthly, although more frequent checks may be necessary in high-demand environments or when transporting abrasive materials.

Related News

Unlocking Efficiency: The Advantages of Customized Three-Roll Idlers for Your Operations

Unlocking Efficiency: The Advantages of Customized Three-Roll Idlers for Your Operations Table of Contents Introduction to Three-Roll Idlers What Are Three-Roll Idlers? The Benefits of Customization Enhanced Performance Through Tailored Solutions Application of Customized Three-Roll Idlers in Various Industries Improving Material Handling Efficiency Maintenance and Durability Consid

Understanding the Importance of Customized Troughing Idler Sets in Material Handling

When it comes to material handling, the efficiency of conveyor systems is paramount. One essential component that significantly impacts this efficiency is the troughing idler set. Customized troughing idler sets are specifically designed to meet the unique requirements of different materials and operational conditions. Understanding their role and advantages can help industries optimize their proc