The Advantages of Using Circular Conveyor Belts in Industrial Operations

25/05/12 13:00

The Advantages of Using Circular Conveyor Belts in Industrial Operations

Introduction to Circular Conveyor Belts

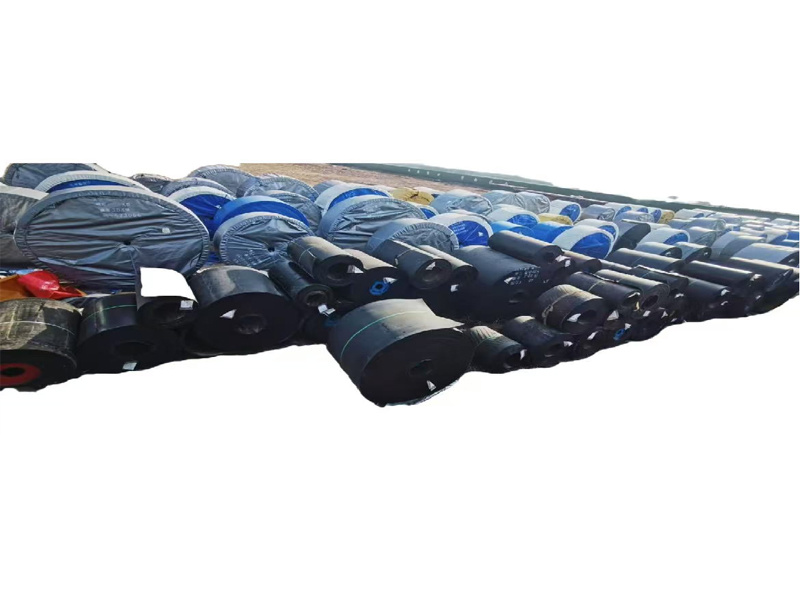

In the ever-evolving world of industrial operations, efficiency and productivity are paramount. One of the key innovations driving these improvements is the **circular conveyor belt**. This system offers a unique design that enables the continuous movement of materials, revolutionizing how businesses transport goods. By understanding the advantages of circular conveyor belts, organizations can make informed decisions that enhance operational efficacy.

Understanding Circular Conveyor Systems

Circular conveyor belts are designed to operate in a loop, facilitating a continuous flow of materials around a designated path. Unlike traditional linear conveyor systems, circular conveyors utilize a more versatile approach, allowing for various configurations and applications. This flexibility is crucial in industries such as manufacturing, packaging, and logistics, where space optimization and product handling are essential.

Key Components of Circular Conveyor Belts

To fully appreciate the advantages of circular conveyor belts, it is essential to understand their key components:

1. Belt Material

The material used for the conveyor belt significantly influences its durability and performance. Common materials include rubber, plastic, and metal, each offering distinct benefits depending on the specific industrial application.

2. Drive Mechanism

The drive mechanism is critical for ensuring smooth movement. Options include electric motors, pneumatic systems, and hydraulic drives, each providing varying levels of power and control.

3. Supporting Structure

The supporting frame must be strong enough to handle the weight of the materials being transported while maintaining stability during operation. This structure can be made from steel, aluminum, or other robust materials.

Why Circular Conveyor Belts Are Essential in Industrial Operations

The integration of circular conveyor belts into industrial operations can deliver numerous benefits, which we will explore in detail below.

1. Enhanced Efficiency in Material Handling

One of the most significant advantages of circular conveyor belts is their ability to enhance material handling efficiency. The continuous movement of materials reduces downtime associated with loading and unloading, allowing for a more streamlined operation. As a result, businesses can achieve higher throughput and meet production demands more effectively.

2. Space Optimization

In many industrial settings, space is a premium. Circular conveyor systems can be configured to take advantage of available space more efficiently than traditional linear conveyors. Their loop design allows for vertical transport, freeing up floor space for other operations. This optimization can significantly impact overall facility layout and productivity.

3. Versatility in Applications

Circular conveyor belts are incredibly versatile, making them suitable for various applications across multiple industries. Whether in food processing, automotive assembly, or packaging, these systems can be adapted to meet specific operational needs. Their ability to handle various materials—from small components to large packages—makes them an invaluable asset in any industrial setting.

4. Reduced Labor Costs

Automation of material handling through circular conveyor systems can lead to a significant reduction in labor costs. By minimizing the need for manual handling, organizations can allocate their workforce to more critical tasks, improving overall productivity. Furthermore, less manual handling also reduces the risk of workplace injuries, promoting a safer work environment.

5. Improved Safety Features

Safety is a paramount concern in industrial operations, and circular conveyor belts can enhance workplace safety. These systems can be equipped with various safety features, including emergency stop buttons, safety guards, and sensors that detect obstructions. By minimizing manual handling and implementing advanced safety technologies, businesses can create a safer working environment for their employees.

6. Increased Flexibility

Circular conveyor belts provide a level of flexibility that is difficult to achieve with traditional conveyors. Their ability to change direction and handle complex layouts allows for customization of material flow. This flexibility is particularly beneficial in dynamic environments where production requirements frequently change.

7. Cost-Effectiveness and Maintenance

While the initial investment in circular conveyor systems may be higher than that of traditional conveyors, the long-term cost savings are significant. The durability and reliability of these systems reduce maintenance costs and downtime, leading to a favorable return on investment. Moreover, many circular conveyor belts are designed for easy maintenance, further enhancing their cost-effectiveness.

8. Energy Efficiency

Modern circular conveyor systems are designed with energy efficiency in mind. Many models incorporate energy-saving technologies that reduce power consumption without sacrificing performance. This not only lowers operational costs but also contributes to a more sustainable industrial operation, aligning with environmentally responsible practices.

Common Applications of Circular Conveyor Belts

The versatility of circular conveyor belts enables their application across various industries, including:

1. Food Processing

In the food industry, circular conveyor systems are ideal for transporting ingredients, packaging products, and managing waste. Their hygienic design and ability to accommodate various temperatures make them perfect for food processing applications.

2. Pharmaceuticals

Pharmaceutical companies utilize circular conveyor belts for efficiently moving products through the production process. These systems ensure consistent product flow while maintaining stringent safety and quality standards.

3. Automotive Manufacturing

The automotive industry benefits from the flexibility of circular conveyor belts in assembly lines. These systems facilitate the quick movement of components, enhancing the overall manufacturing process.

4. Packaging and Distribution

In packaging and distribution centers, circular conveyors streamline the sorting and distribution of products. Their efficient design minimizes handling time, allowing for faster order fulfillment.

Factors to Consider When Implementing Circular Conveyor Systems

Before integrating circular conveyor belts into your operations, several factors must be considered to ensure optimal performance:

1. Type of Materials Handled

Understanding the types of materials you will be transporting is crucial in selecting the appropriate conveyor belt material and design. Heavy, abrasive materials may require more robust belt options, while lighter items may allow for more flexibility.

2. Space Constraints

Assessing your facility's layout and space availability is essential for designing an effective circular conveyor system. Proper planning will ensure that the system is both efficient and space-saving.

3. Production Requirements

Evaluating your production demands will help determine the speed, size, and capacity of the circular conveyor system needed. It's essential to align the conveyor capabilities with your operational goals.

Frequently Asked Questions

1. What are the primary benefits of circular conveyor belts?

Circular conveyor belts enhance efficiency, optimize space, reduce labor costs, and improve safety features in industrial operations.

2. In which industries are circular conveyor belts most commonly used?

Circular conveyor belts are widely used in food processing, pharmaceuticals, automotive manufacturing, and packaging and distribution.

3. How do circular conveyor systems improve safety?

These systems can be equipped with safety features such as emergency stops, safety guards, and obstruction sensors, minimizing the risk of workplace injuries.

4. Are circular conveyor belts energy-efficient?

Yes, modern circular conveyor systems are designed with energy efficiency in mind, often incorporating technologies that reduce power consumption.

5. What factors should be considered when implementing a circular conveyor system?

Key factors include the type of materials handled, space constraints, and production requirements to ensure optimal performance.

Conclusion

In conclusion, circular conveyor belts present a multitude of advantages that can transform industrial operations. From enhancing efficiency and improving safety to reducing labor costs and optimizing space, these systems are integral to modern manufacturing and logistics. By considering the specific needs of your operation and investing in a suitable circular conveyor system, organizations can achieve significant improvements in productivity and cost-effectiveness. The future of industrial operations is increasingly leaning toward innovative solutions like circular conveyor belts, making them a critical component of any forward-thinking business strategy.

Related News

Unlocking Efficiency: The Advantages of Customized Three-Roll Idlers for Your Operations

Unlocking Efficiency: The Advantages of Customized Three-Roll Idlers for Your Operations Table of Contents Introduction to Three-Roll Idlers What Are Three-Roll Idlers? The Benefits of Customization Enhanced Performance Through Tailored Solutions Application of Customized Three-Roll Idlers in Various Industries Improving Material Handling Efficiency Maintenance and Durability Consid

Understanding the Importance of Customized Troughing Idler Sets in Material Handling

When it comes to material handling, the efficiency of conveyor systems is paramount. One essential component that significantly impacts this efficiency is the troughing idler set. Customized troughing idler sets are specifically designed to meet the unique requirements of different materials and operational conditions. Understanding their role and advantages can help industries optimize their proc