Understanding Mining Machine Roller Supports: Essential Components for Efficient Operations

25/09/11 19:09

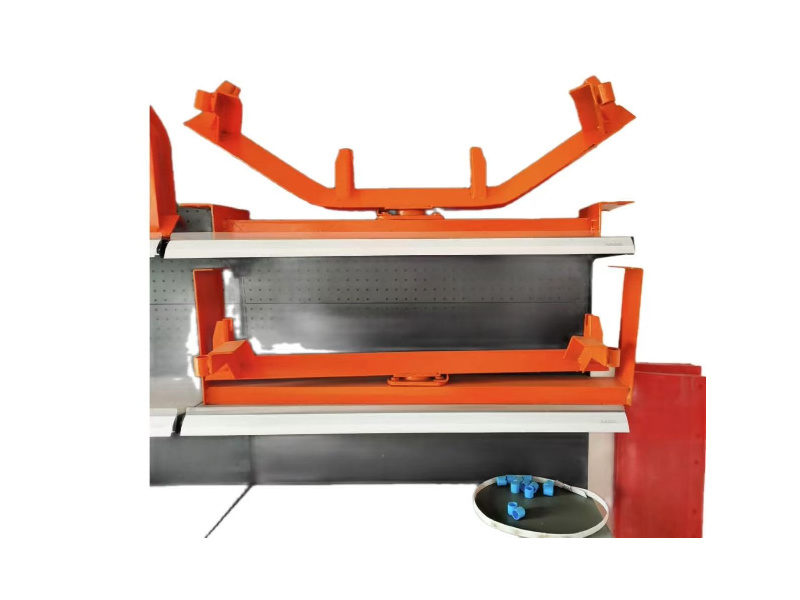

At their core, roller supports are designed to bear and distribute the weight of the machinery they are part of. They provide stability and support to components that experience significant stress during operation. In the context of mining machinery, these supports help to optimize the performance of equipment like crushers, screens, and separators, which are essential for breaking down and sorting mined materials.

One of the primary benefits of using high-quality roller supports is their ability to reduce friction and wear on moving parts. This is particularly important in mining applications where heavy loads and harsh conditions can lead to premature equipment failure. By minimizing friction, roller supports help to prolong the lifespan of the machinery, reducing downtime and maintenance costs.

Moreover, the design of roller supports can vary depending on the specific type of machinery and the nature of the materials being processed. Some roller supports feature adjustable height settings, allowing for better alignment and leveling of equipment. This adaptability is crucial in mining operations where terrain and material characteristics can vary widely. When properly installed and maintained, roller supports can contribute to improved operational efficiency and productivity.

It is also essential to consider the material and construction of roller supports. High-strength materials are often used to withstand the rigorous demands of mining operations. The use of durable materials ensures that the roller supports can endure the harsh environments typically encountered in mining applications, including exposure to dust, moisture, and varying temperatures.

In conclusion, mining machine roller supports are integral to the effective functioning of crushing and sorting machinery within the manufacturing and processing industry. By providing stability, reducing friction, and enabling adaptability, these components enhance the overall performance of mining equipment. Understanding their importance can lead to improved operational efficiency and longevity of machinery, ultimately contributing to more successful mining operations. As industries continue to evolve, investing in high-quality roller supports will remain a key factor in optimizing machinery performance and achieving productive outcomes in the mining sector.

Related News

Unlocking Efficiency: The Advantages of Customized Three-Roll Idlers for Your Operations

Unlocking Efficiency: The Advantages of Customized Three-Roll Idlers for Your Operations Table of Contents Introduction to Three-Roll Idlers What Are Three-Roll Idlers? The Benefits of Customization Enhanced Performance Through Tailored Solutions Application of Customized Three-Roll Idlers in Various Industries Improving Material Handling Efficiency Maintenance and Durability Consid

Understanding the Importance of Customized Troughing Idler Sets in Material Handling

When it comes to material handling, the efficiency of conveyor systems is paramount. One essential component that significantly impacts this efficiency is the troughing idler set. Customized troughing idler sets are specifically designed to meet the unique requirements of different materials and operational conditions. Understanding their role and advantages can help industries optimize their proc