Why You Should Consider a Durable Circular Conveyor Belt for Your Operations

25/06/11 11:00

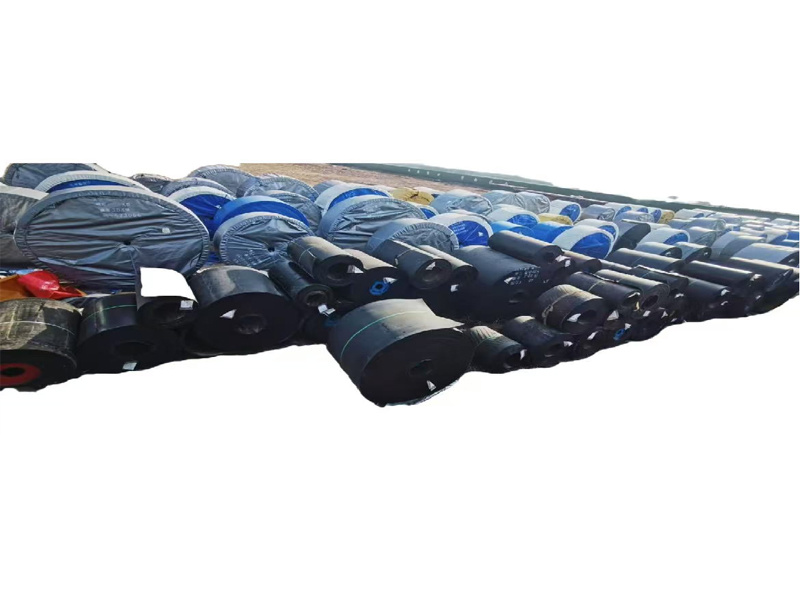

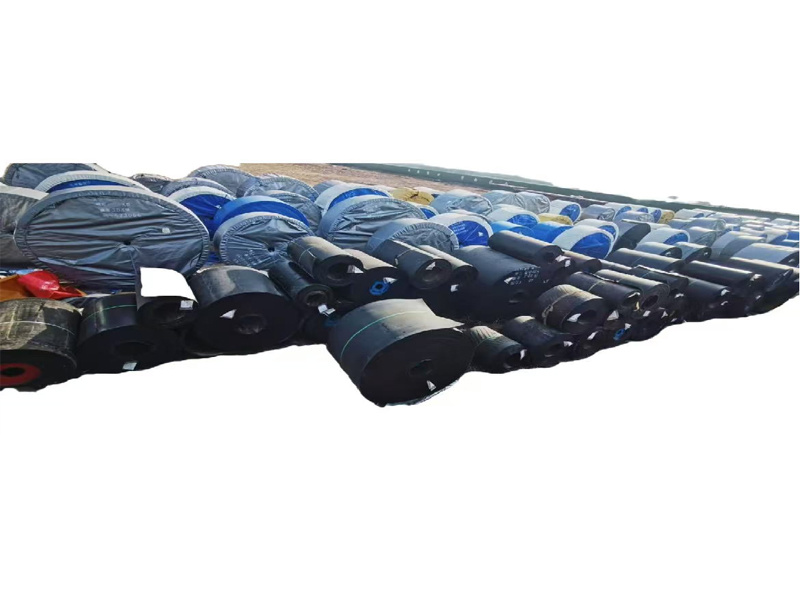

A circular conveyor belt is a crucial component in various industrial operations, designed to transport materials efficiently within a closed-loop system. Unlike traditional conveyor systems that operate linearly, circular conveyor belts facilitate continuous movement, enhancing workflow and minimizing downtime. These belts are engineered for durability, making them ideal for heavy-duty applications in sectors such as manufacturing, food processing, and logistics.

The Importance of Durability in Conveyor Belts

Why Durability Matters

In industrial settings, the longevity of equipment directly impacts productivity and operational costs. A durable circular conveyor belt can withstand harsh conditions, including extreme temperatures, heavy loads, and abrasive materials. Investing in a high-quality conveyor belt reduces the need for frequent replacements and repairs, thereby lowering maintenance costs and minimizing unplanned downtime.

Key Features of Durable Circular Conveyor Belts

Durable circular conveyor belts are characterized by several key features that enhance their performance and lifespan:

- Robust Material Construction: Often made from high-strength materials such as PVC, polyurethane, or rubber, these belts are designed to endure wear and tear.

- Resistance to Chemicals: Many industrial operations involve exposure to corrosive substances. High-quality conveyor belts are formulated to resist chemical damage, ensuring reliability.

- Temperature Tolerance: These belts can function effectively in extreme temperatures, making them suitable for various applications, from freezing environments to high-heat processes.

Applications of Circular Conveyor Belts

Manufacturing Industry

In the manufacturing sector, circular conveyor belts are pivotal in automating processes. They facilitate the efficient movement of raw materials, components, and finished products within a facility. This automation not only speeds up production but also reduces labor costs.

Food Processing Industry

The food processing industry relies heavily on circular conveyor belts for transporting products in a hygienic and efficient manner. These belts are designed to meet stringent food safety standards, ensuring that food products are handled safely throughout the processing stages.

Logistics and Warehousing

In logistics and warehousing, circular conveyor belts streamline the movement of goods, improving order fulfillment efficiency. By integrating these systems, businesses can achieve faster packing, sorting, and shipping processes, ultimately enhancing customer satisfaction.

Choosing the Right Circular Conveyor Belt

Factors to Consider

When selecting a durable circular conveyor belt for your operations, consider the following factors:

- Load Capacity: Assess the maximum weight that the belt will need to carry to ensure it meets your operational demands.

- Belt Width and Length: Customize the dimensions of the conveyor belt to fit your specific setup and space constraints.

- Environment Conditions: Evaluate the operating environment, including temperature, humidity, and exposure to chemicals, to select the most suitable material.

- Maintenance Requirements: Understand the maintenance needs of different types of conveyor belts to choose one that fits your operational capabilities.

Consulting with Industry Experts

Engaging with industry experts can provide valuable insights into selecting the right circular conveyor belt. Professionals can help assess your unique requirements and suggest suitable options that align with your business goals.

Benefits of Investing in Durable Circular Conveyor Belts

Enhanced Productivity

Durable circular conveyor belts contribute to increased productivity by minimizing disruptions in the material handling process. Their continuous operation allows for smooth transitions between different stages of production, reducing the time spent on manual handling.

Cost Savings

While the initial investment in high-quality circular conveyor belts may be higher than cheaper alternatives, the long-term cost savings are significant. Reduced maintenance costs and fewer replacements lead to a lower total cost of ownership over time.

Improved Safety

Safety is a paramount concern in industrial operations. Durable conveyor belts designed with safety features, such as anti-slip surfaces and emergency stop mechanisms, contribute to a safer work environment, reducing the risk of accidents.

Maintenance Tips for Circular Conveyor Belts

Regular Inspections

Conducting regular inspections is essential to identify potential issues before they escalate. Check for signs of wear, misalignment, and loose components to ensure the conveyor belt operates efficiently.

Cleaning and Lubrication

Keeping the conveyor belt clean and properly lubricated is vital for maintaining its performance. Remove debris and contaminants that can cause damage and ensure moving parts are adequately lubricated to reduce friction.

Professional Servicing

Consider scheduling periodic professional servicing to evaluate the condition of the conveyor belt and perform necessary repairs. Expert technicians can provide insights that may not be apparent during routine inspections.

Incorporating a durable circular conveyor belt into your operations is a strategic decision that can significantly enhance productivity, reduce costs, and improve workplace safety. By understanding the features, applications, and maintenance needs of these systems, you position your business for long-term success. Investing in high-quality equipment today will yield substantial benefits for your operations in the future, ensuring that your processes run smoothly and efficiently.

Related News

Understanding the Benefits and Uses of New Carriage Bolts in Industrial Applications

Carriage bolts are essential components in various industrial applications, primarily due to their unique design and robust functionality. The latest developments in new carriage bolts have introduced enhancements that improve their performance and versatility, making them a preferred choice for many industries. A carriage bolt, characterized by its round head and square neck, is designed to be in

Why You Should Consider a Durable Circular Conveyor Belt for Your Operations

Incorporating a durable circular conveyor belt into your operations is a strategic decision that can significantly enhance productivity, reduce costs, and improve workplace safety