Maximizing Conveyor Performance with Three-Roll Idler Systems: A Comprehensive Guide

25/03/28 12:40

Maximizing Conveyor Performance with Three-Roll Idler Systems

Conveyor systems play a crucial role in material handling across various industries, from mining and manufacturing to logistics and distribution. The performance of these systems directly affects productivity and operational efficiency. One of the key components that can significantly influence conveyor performance is the idler system. In this article, we explore how **three-roll idler systems** can maximize conveyor performance, delving into their mechanics, advantages, and applications.

Table of Contents

1. Introduction to Conveyor Systems and Idler Rollers

2. What Are Three-Roll Idlers?

3. Advantages of Three-Roll Idler Systems in Conveyors

- 3.1 Enhanced Load Support

- 3.2 Reduced Friction and Wear

- 3.3 Improved Material Handling

4. The Mechanics of Three-Roll Idler Systems

- 4.1 Roll Arrangement and Configuration

- 4.2 Load Distribution and Dynamics

5. Applications of Three-Roll Idler Systems

- 5.1 In the Mining Industry

- 5.2 In the Manufacturing Industry

- 5.3 In Logistics and Distribution

6. Maintenance Tips and Best Practices

7. Future Trends in Idler Systems

8. Conclusion

9. Frequently Asked Questions (FAQs)

Introduction to Conveyor Systems and Idler Rollers

Conveyor systems are essential for transporting materials in a wide range of industries. They consist of various components, including belts, pulleys, and idlers. **Idlers** are critical elements that support the conveyor belt and contribute to its operational efficiency. Understanding the different types of idlers, particularly **three-roll idler systems**, is essential for optimizing conveyor performance.

What Are Three-Roll Idlers?

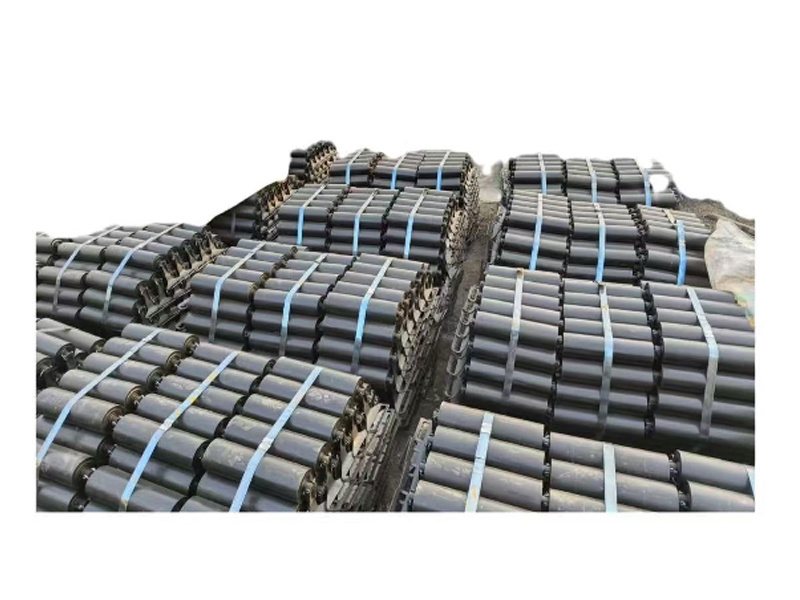

Three-roll idlers consist of three cylindrical rolls arranged in a triangular configuration. This unique arrangement allows for enhanced material support and stability compared to traditional two-roll idler systems. The design minimizes belt sagging, improves load distribution, and enhances the overall efficiency of the conveyor system.

Advantages of Three-Roll Idler Systems in Conveyors

Three-roll idler systems offer several advantages that can significantly impact conveyor performance. Below are some key benefits:

Enhanced Load Support

Three-roll idler systems provide superior load support due to their triangular configuration. The additional roll ensures that the weight of the conveyed materials is evenly distributed, reducing the risk of belt deformation and ensuring smooth operation. This is particularly beneficial when transporting heavy or bulky materials.

Reduced Friction and Wear

The design of three-roll idlers minimizes the contact area between the rolls and the conveyor belt, leading to reduced friction. Lower friction translates to less wear and tear on both the idlers and the belt, extending the lifespan of conveyor components and reducing maintenance costs.

Improved Material Handling

Three-roll idlers enhance material handling capabilities by stabilizing the belt during operation. This stability is vital for transporting materials over long distances or on inclines, where deviations can lead to spillage or misalignment. Improved material handling translates to more efficient operations and less downtime.

The Mechanics of Three-Roll Idler Systems

Understanding the mechanics of three-roll idler systems is essential for optimizing their performance. Key factors include roll arrangement and load distribution.

Roll Arrangement and Configuration

The triangular arrangement of three rolls allows for balanced support across the width of the conveyor belt. This configuration minimizes belt sag and improves the flow of materials, ensuring that the system operates efficiently. The angle at which the rolls are positioned can also be adjusted to suit specific material handling needs.

Load Distribution and Dynamics

Load distribution is critical in conveyor systems, especially when transporting heavy materials. Three-roll idlers distribute the load evenly across the belt, preventing excessive wear on any single point. This uniform load distribution contributes to a longer lifespan for both the conveyor belt and the idlers themselves.

Applications of Three-Roll Idler Systems

Three-roll idler systems find applications across various industries, each benefiting from their unique features. Here are some key applications:

In the Mining Industry

In mining operations, conveyor systems are essential for transporting extracted materials. Three-roll idler systems provide the necessary support and stability for heavy loads, making them ideal for moving ore, coal, and other materials over long distances.

In the Manufacturing Industry

Manufacturers rely on conveyor systems to move products through assembly lines. The enhanced load support and reduced friction offered by three-roll idlers help streamline production processes, ensuring that materials are transported efficiently between different stages of production.

In Logistics and Distribution

In logistics and distribution centers, conveyor systems are crucial for moving products quickly and efficiently. Three-roll idler systems enhance the stability and reliability of these conveyors, reducing the risk of product loss and improving overall workflow.

Maintenance Tips and Best Practices

To ensure the longevity and optimal performance of three-roll idler systems, regular maintenance is essential. Here are some best practices:

1. **Regular Inspections:** Conduct routine inspections of the idlers for signs of wear, misalignment, or damage.

2. **Cleaning:** Keep the idlers clean to prevent buildup of dirt and debris, which can lead to increased wear and friction.

3. **Lubrication:** Ensure that moving parts are properly lubricated to minimize friction and wear.

4. **Alignment Checks:** Regularly check the alignment of the conveyor system to prevent undue stress on the idlers and belt.

5. **Replace Worn Components:** Promptly replace any worn or damaged idlers to maintain system efficiency.

Future Trends in Idler Systems

As technology continues to evolve, so do conveyor systems and idler technologies. Some emerging trends include:

- **Smart Idler Systems:** Incorporating sensors for real-time monitoring of idler performance to prevent failures and reduce maintenance costs.

- **Sustainable Materials:** Using eco-friendly materials for idler construction to enhance sustainability in manufacturing processes.

- **Automation:** Integrating automation technologies to improve the efficiency of conveyor systems and reduce operational costs.

Conclusion

Three-roll idler systems are a game-changer in maximizing conveyor performance. Their unique design offers numerous advantages, including enhanced load support, reduced friction, and improved material handling. As industries continue to evolve, the demand for efficient and reliable conveyor systems will increase, making the understanding and implementation of three-roll idler systems essential for success.

Frequently Asked Questions (FAQs)

1. What is a three-roll idler system?

A three-roll idler system consists of three cylindrical rolls arranged in a triangular configuration to provide enhanced support and stability for conveyor belts.

2. How do three-roll idlers improve conveyor performance?

They improve performance by distributing loads evenly, reducing friction and wear, and stabilizing the conveyor belt during operation.

3. In which industries are three-roll idler systems commonly used?

They are commonly used in mining, manufacturing, and logistics industries, where transporting heavy materials is crucial.

4. How can I maintain three-roll idler systems?

Regular inspections, cleaning, lubrication, alignment checks, and timely replacement of worn components are essential for maintenance.

5. Are there any future trends in idler systems?

Yes, trends include the development of smart idler systems, sustainable materials, and automation technologies to enhance conveyor efficiency.

Related News

Unlocking Efficiency: The Advantages of Customized Three-Roll Idlers for Your Operations

Unlocking Efficiency: The Advantages of Customized Three-Roll Idlers for Your Operations Table of Contents Introduction to Three-Roll Idlers What Are Three-Roll Idlers? The Benefits of Customization Enhanced Performance Through Tailored Solutions Application of Customized Three-Roll Idlers in Various Industries Improving Material Handling Efficiency Maintenance and Durability Consid

Understanding the Importance of Customized Troughing Idler Sets in Material Handling

When it comes to material handling, the efficiency of conveyor systems is paramount. One essential component that significantly impacts this efficiency is the troughing idler set. Customized troughing idler sets are specifically designed to meet the unique requirements of different materials and operational conditions. Understanding their role and advantages can help industries optimize their proc