Discover the Unique Features of the Newest Three-Roll Idler: A Comprehensive Guide

25/06/07 11:40

Discover the Unique Features of the Newest Three-Roll Idler

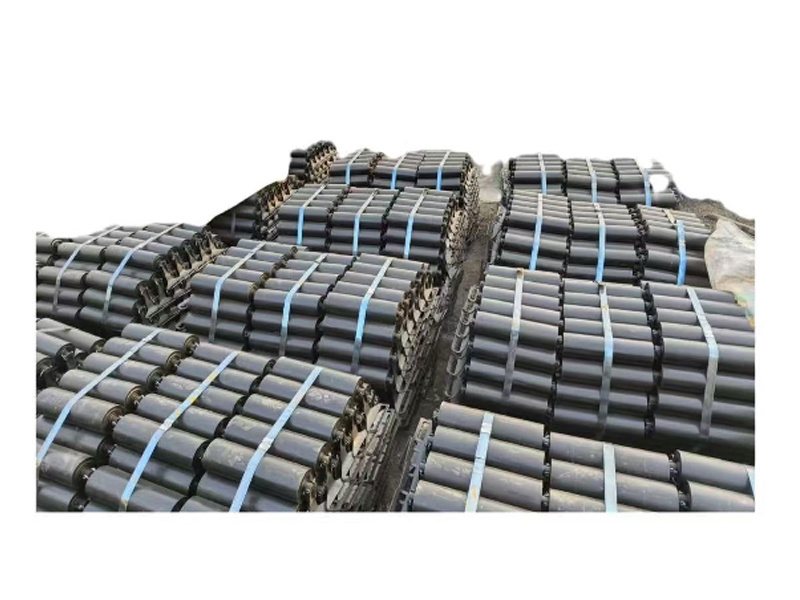

In the fast-evolving world of hardware tools and accessories, innovations continuously enhance efficiency and effectiveness. Among these developments, the newest three-roll idler stands out for its unique design and functionality. This article delves into the distinct features of this idler, highlighting its benefits, applications, and the reasons why it has become an essential component in various industries.

Understanding the Three-Roll Idler

What is a Three-Roll Idler?

A three-roll idler is a crucial component used in conveyor systems, facilitating the smooth movement of materials. Unlike traditional idlers, which typically feature two rolls, the three-roll design provides enhanced stability and support for conveyed materials. This innovation minimizes spillage and ensures a reliable flow, making it an invaluable asset in manufacturing, mining, and construction settings.

The Mechanism Behind the Three-Roll Design

The three-roll idler operates on a simple yet effective principle: by distributing the load across three rolls, it can support heavier materials while maintaining balance. The rolls are strategically positioned to create a triangular formation, which optimizes the load-bearing capacity and significantly reduces wear and tear on conveyor belts. This design not only enhances the efficiency of material handling but also extends the lifespan of the equipment.

Key Features of the Newest Three-Roll Idler

1. Enhanced Load Capacity

One of the standout features of the newest three-roll idler is its enhanced load capacity. With the ability to support heavier loads compared to traditional two-roll designs, this idler is perfect for industries dealing with substantial materials. Whether it's heavy metals in mining or bulk products in manufacturing, the three-roll idler can handle it all without compromising performance.

2. Improved Stability and Reduction of Spillage

The triangular arrangement of the rolls provides superior stability. This stability is crucial in preventing material spillage, particularly when handling loose or granular substances. By minimizing spillage, businesses can reduce waste, optimize material usage, and ultimately lower operational costs.

3. Increased Durability

Built with high-quality materials, the newest three-roll idler is designed to withstand harsh environmental conditions. Its robust construction ensures that it remains functional under extreme temperatures, humidity, and abrasive materials, which are common in various industrial applications. This durability translates to less frequent replacements and lower maintenance costs.

4. Versatile Applications

The versatility of the three-roll idler makes it suitable for a wide range of applications. From mining operations to food processing plants, this idler can be tailored to meet specific requirements. Its adaptability in various settings is a significant advantage for companies looking to streamline their operations.

5. Easy Installation and Maintenance

Another compelling feature is the ease of installation and maintenance. The three-roll idler is designed to be user-friendly, allowing for quick setup without the need for extensive modifications to existing conveyor systems. Additionally, its simple design facilitates straightforward maintenance, ensuring that downtime is minimized and productivity is maximized.

Benefits of Implementing the Three-Roll Idler

1. Cost-Effectiveness

Investing in the newest three-roll idler can lead to significant cost savings. Its durability means fewer replacements, while its efficiency in handling materials reduces operational costs associated with spillage and waste. Companies can expect a solid return on investment when incorporating this idler into their systems.

2. Enhanced Operational Efficiency

The three-roll design not only improves load handling but also enhances the overall efficiency of conveyor systems. By ensuring smooth material flow and reducing the risk of blockages or delays, businesses can optimize their production processes, ultimately leading to increased output and profitability.

3. Environmental Sustainability

With an emphasis on reducing waste and improving material handling efficiency, the three-roll idler contributes to more sustainable industrial practices. By minimizing spillage and ensuring that materials are conveyed without loss, companies can operate more environmentally responsibly, aligning with modern sustainability goals.

Choosing the Right Three-Roll Idler for Your Needs

Assessing Your Material Handling Requirements

When selecting a three-roll idler, it’s essential to assess the specific requirements of your material handling operations. Factors such as the type of materials, load weight, and environmental conditions should all be considered. This assessment will help identify the most appropriate design and specifications for your idler.

Consulting with Experts

Engaging with industry professionals can provide valuable insights into the best three-roll idler options available. Experts can help you navigate the various models and features, ensuring that you choose an idler that meets your operational needs and enhances your overall efficiency.

Understanding Maintenance Needs

Before making your selection, it is crucial to understand the maintenance requirements of different three-roll idlers. Some models may require more frequent servicing than others, which can impact long-term costs and operational efficiency. Choosing a model with straightforward maintenance procedures can save time and resources in the long run.

FAQs about the Three-Roll Idler

1. What are the primary industries that use three-roll idlers?

Three-roll idlers are widely used in mining, manufacturing, construction, and food processing industries, where efficient material handling is essential.

2. How does the three-roll design benefit material handling?

The triangular design improves stability, enhances load capacity, and reduces spillage, making it more effective for handling various materials.

3. Are three-roll idlers compatible with all conveyor systems?

Yes, three-roll idlers can be adapted to fit most conveyor systems, though specific adjustments may be needed based on the existing setup.

4. What maintenance practices are recommended for three-roll idlers?

Regular inspections, lubrication of moving parts, and cleaning debris from the rolls are key practices to ensure optimal performance and longevity.

5. How do three-roll idlers compare to two-roll idlers?

Three-roll idlers offer enhanced stability, improved load capacity, and reduced spillage compared to traditional two-roll designs, making them a superior choice for many applications.

Conclusion

The newest three-roll idler represents a significant advancement in material handling technology. With its unique design, enhanced load capacity, and versatile applications, it has become an indispensable component in various industries. By understanding its features, benefits, and the importance of selecting the right idler for your needs, businesses can optimize their operations and achieve greater efficiency. Embracing innovations like the three-roll idler can lead to improved productivity, cost savings, and a smaller environmental footprint, paving the way for a more sustainable future in industrial practices.

Previous Page:

Related News

Understanding Quality Pipe Seam Anchor Rods in Construction

In the construction and decoration industry, particularly within the realm of piping systems, quality pipe seam anchor rods play a vital role. These components are specially designed to provide structural support and stability to pipes, ensuring they remain securely anchored in place. The effectiveness of a piping system largely depends on how well it is supported, making the selection of high-qua

Discover the Unique Features of the Newest Three-Roll Idler: A Comprehensive Guide

Discover the Unique Features of the Newest Three-Roll Idler In the fast-evolving world of hardware tools and accessories, innovations continuously enhance efficiency and effectiveness. Among these developments, the newest three-roll idler stands out for its unique design and functionality. This article delves into the distinct features of this idler, highlighting its benefits, applications, and th