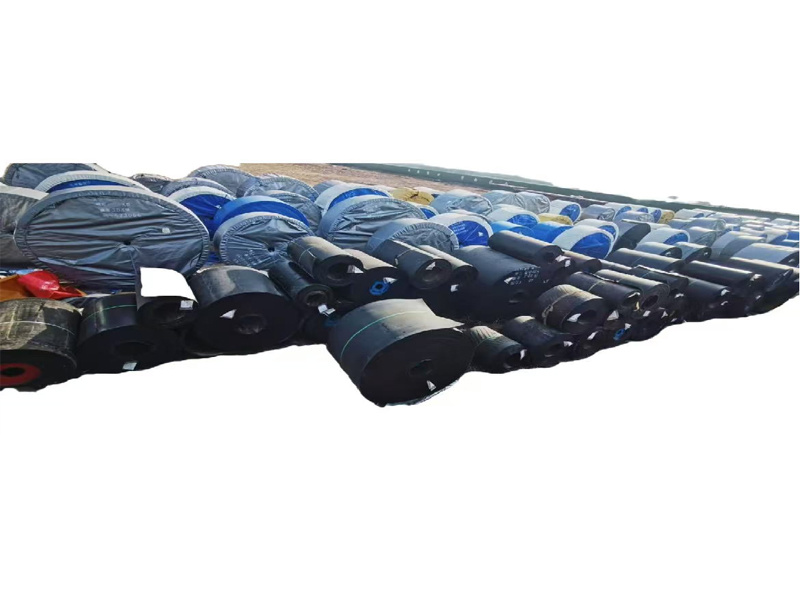

Circular Conveyor Belts: A Key Component in Automated Systems

25/06/01 13:40

Circular conveyor belts are specialized conveying systems characterized by their continuous loop design, allowing for efficient transport of items around a circuit. Unlike traditional linear conveyor systems, these belts create a circular path, enabling materials to be recycled through the system without the need for manual handling.

The Mechanism Behind Circular Conveyor Belts

The operational efficiency of circular conveyor belts lies in their **mechanical design**. Typically driven by motors, these systems utilize pulleys and tensioning mechanisms to maintain a consistent speed and movement. The continuous loop reduces wear and tear, making them ideal for high-volume applications.

The Importance of Circular Conveyor Belts in Automated Systems

Circular conveyor belts play a crucial role in the overall functionality of **automated systems**. Their significance can be attributed to several factors:

Enhanced Efficiency

By facilitating uninterrupted movement of goods, circular conveyor belts significantly reduce cycle times. This leads to improved throughput and productivity, which are essential for meeting market demands.

Reduced Labor Costs

Automation minimizes the need for manual handling, thereby reducing labor costs associated with transportation and logistics. Circular conveyor belts efficiently handle the movement of materials, allowing human resources to focus on more strategic tasks.

Improved Safety

With the automation of material handling, the risk of workplace injuries decreases. Circular conveyor belts reduce the need for workers to engage in repetitive manual lifting, promoting a safer work environment.

Design and Architecture of Circular Conveyor Belts

The design of circular conveyor belts is crucial for their functionality and efficiency. Various factors influence their architecture, including the type of materials they transport, the operational environment, and the specific needs of the application.

Materials Used in Construction

Circular conveyor belts are made from a variety of materials, each selected based on the application requirements. Common materials include:

- **Polyurethane**: Known for its durability and resistance to wear.

- **Rubber**: Provides excellent traction and flexibility.

- **Metal**: Used for heavy-duty applications requiring strength and resilience.

Different Types of Circular Conveyor Belts

There are several types of circular conveyor belts designed for specific applications:

1. **Modular Belts**: Composed of interlocking plastic modules, offering flexibility and easy maintenance.

2. **Wire Mesh Belts**: Ideal for high-temperature applications due to their excellent airflow.

3. **Fabric Belts**: Common in lighter-duty applications, providing ease of handling and installation.

Applications of Circular Conveyor Belts Across Industries

Circular conveyor belts find applications in various industries, enhancing efficiency and productivity. Key sectors include:

Manufacturing

In manufacturing settings, circular conveyor belts streamline the production line by transporting components seamlessly between workstations, reducing downtime.

Food and Beverage Industry

These belts are essential in the food industry for transporting products through various stages of processing and packaging while meeting strict hygiene standards.

Logistics and Warehousing

In logistics, circular conveyor belts facilitate the movement of goods through sorting and distribution centers, improving order fulfillment times and inventory management.

Automotive Sector

In automotive manufacturing, circular conveyor belts play a pivotal role in the assembly process, ensuring components are delivered to the assembly line efficiently.

Innovations in Circular Conveyor Belt Technology

The evolution of circular conveyor belts continues with advancements in technology. Key innovations include:

Smart Conveyor Systems

Integrating sensors and automation, smart conveyor systems provide real-time data on performance, allowing for predictive maintenance and enhanced operational efficiency.

Eco-Friendly Materials

The industry is shifting towards sustainable materials, reducing environmental impact without compromising performance.

Modular Design Enhancements

Advancements in modular design allow for easier customization and scalability, enabling businesses to adapt their systems as needs change.

Maintenance and Care for Optimal Performance

Proper maintenance of circular conveyor belts is essential to ensure longevity and performance. Key practices include:

Regular Inspections

Conducting routine inspections to identify signs of wear, misalignment, or damage can prevent costly breakdowns.

Lubrication

Regular lubrication of moving parts is crucial for reducing friction and extending the lifespan of the conveyor system.

Cleaning

Maintaining cleanliness on the conveyor surface is vital, particularly in food handling operations, to prevent contamination.

Conclusion

Circular conveyor belts are indispensable components in today's automated systems, driving efficiency, safety, and productivity across industries. With continuous innovations in design and technology, these belts are poised to meet the evolving demands of material handling. Understanding their significance and proper maintenance will empower businesses to harness their full potential in optimizing operational workflows.

Related News

Understanding Quality Pipe Seam Anchor Rods in Construction

In the construction and decoration industry, particularly within the realm of piping systems, quality pipe seam anchor rods play a vital role. These components are specially designed to provide structural support and stability to pipes, ensuring they remain securely anchored in place. The effectiveness of a piping system largely depends on how well it is supported, making the selection of high-qua

Discover the Unique Features of the Newest Three-Roll Idler: A Comprehensive Guide

Discover the Unique Features of the Newest Three-Roll Idler In the fast-evolving world of hardware tools and accessories, innovations continuously enhance efficiency and effectiveness. Among these developments, the newest three-roll idler stands out for its unique design and functionality. This article delves into the distinct features of this idler, highlighting its benefits, applications, and th